Endoscopio industriale ad alta temperatura: Una soluzione all'avanguardia per condizioni estreme

Nella moderna produzione industriale, La sicurezza e l'affidabilità delle attrezzature sono cruciali per il funzionamento delle imprese. Soprattutto in ambienti con alte temperature, alta pressione, e spazi confinati, I limiti dei metodi di ispezione tradizionali diventano sempre più evidenti. Ciò crea una domanda di strumenti di ispezione in grado di resistere alle condizioni estreme pur essendo portatili. L'avvento dell'endoscopio industriale ad alta temperatura di 1000 ° C è una soluzione eccezionale per questa necessità.

1. Progettato per ambienti estremi

In molte applicazioni industriali, come la generazione di energia, metallurgia, e petrolchimici, L'attrezzatura è spesso esposta ad ambienti ad alta temperatura. Gli strumenti di ispezione tradizionali spesso non possono resistere a temperature operative così elevate, Ma l'endoscopio industriale ad alta temperatura di 1000 ° C cambia completamente questo scenario. Utilizza materiali avanzati e principi di progettazione che consentono all'endoscopio di funzionare in modo sicuro e stabilmente in ambienti fino a 1000 ° C, Garantire che possa trasmettere immagini chiare anche in condizioni estreme.

Questa funzione rende l'endoscopio particolarmente adatto per situazioni di manutenzione ad alta temperatura come le caldaie, Forni, e reattori. Se ispezionare le condizioni di combustione all'interno di un inceneritore o monitorare lo stato operativo di un forno di fusione metallica, L'endoscopio può fornire un feedback preciso per una rapida identificazione di potenziali problemi e una manutenzione adeguata.

2. Design portatile Miglioramento della flessibilità in loco

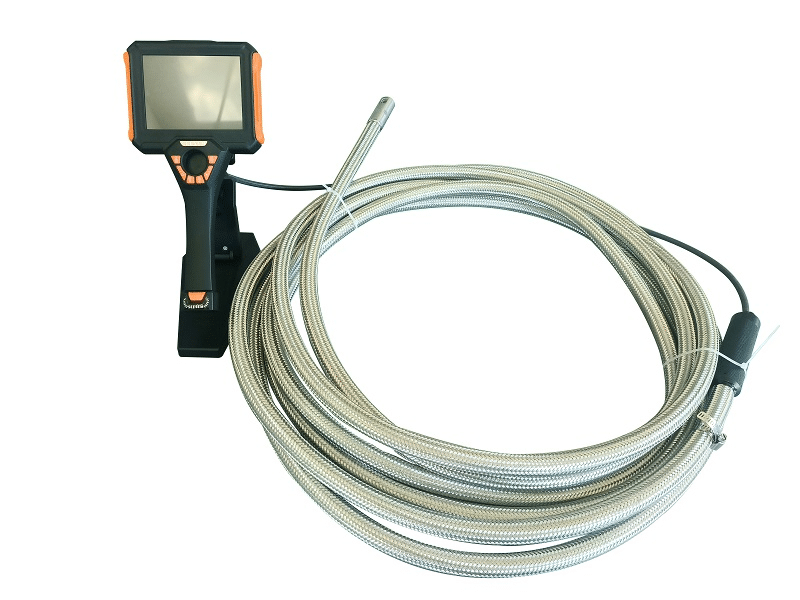

Su siti industriali, L'ispezione dell'attrezzatura deve spesso verificarsi in spazi complessi o confinati, dove i dispositivi di ispezione tradizionali possono essere ingombranti. La progettazione portatile dell'endoscopio industriale ad alta temperatura di 1000 ° C affronta perfettamente questo problema. Questo endoscopio non è solo leggero ma anche facile da usare, rendendo comodo il trasporto e l'uso in loco.

Il suo design compatto consente agli utenti di trasportarlo facilmente su qualsiasi sito di ispezione richiesto, Sia che si tratti di lavorare in alto o navigare nei tunnel sotterranei. Inoltre, la sonda, che può superare 10 metri di lunghezza, espande la gamma di rilevamento. Una sonda da 10 metri può raggiungere gli spazi stretti, tubi, e aree inaccessibili dell'attrezzatura, Garantire che gli ispettori possano effettuare controlli in modo sicuro ed efficiente in ambienti pericolosi. La flessibilità dell'endoscopio rende abile nel gestire condutture lunghe e strutture di montaggio complesse.

3. Imaging efficiente e trasmissione dei dati

Un altro vantaggio significativo dell'endoscopio industriale ad alta temperatura è la sua eccezionale capacità di imaging. Dotato di un sensore di immagine ad alta risoluzione, Questo dispositivo può catturare chiaro, Immagini dettagliate in tempo reale. Anche in ambienti ad alta temperatura e condizioni in condizioni di scarsa illuminazione, Questo endoscopio ad alta temperatura può ancora fornire immagini di qualità, consentendo agli ispettori di identificare prontamente i problemi.

Inoltre, Gli endoscopi moderni vanno oltre l'acquisizione di immagini di base; Molti modelli supportano la registrazione video e le funzionalità di trasmissione dei dati in tempo reale. Che si tratti di trasmettere immagini a dispositivi mobili in loco o di inviare informazioni a un centro di monitoraggio, Gli ispettori possono analizzare rapidamente e prendere decisioni. Questa capacità di condivisione dei dati migliora notevolmente l'efficienza dell'ispezione, Aiutare a correggere prontamente i guasti delle apparecchiature e ridurre al minimo i tempi di inattività, In definitiva abbassare i costi operativi per le imprese.

4. Ridurre i rischi e migliorare la sicurezza

La sicurezza in ambienti industriali è un fattore critico che non può essere trascurato. In operazioni ad alta temperatura, Gli ispettori affrontano spesso enormi rischi. Usando un endoscopio ad alta temperatura di 1000 ° C per le ispezioni, Il personale può mantenere una distanza di sicurezza dai componenti ad alta temperatura, Ridurre la probabilità di incidenti con lesioni personali.

Inoltre, Questo endoscopio industriale è dotato di molteplici impostazioni di protezione per prevenire i danni alle attrezzature in condizioni anormali, Garantire un funzionamento stabile per lunghi periodi. Queste misure di sicurezza proteggono efficacemente sia l'attrezzatura che gli operatori, Garantire la sicurezza delle operazioni industriali.

5. Benefici economici e sviluppo sostenibile

Sebbene l'investimento iniziale in un endoscopio ad alta temperatura possa essere relativamente alto, La migliore efficienza di ispezione e la riduzione dei costi di manutenzione rendono questo dispositivo altamente economico a lungo termine. Scoprendo e affrontando tempestivamente i problemi delle attrezzature, Le imprese non possono solo ridurre i tempi di inattività, ma anche estendere la durata della vita dell'attrezzatura, Abbassando significativamente i costi di riparazione e sostituzione. Inoltre, L'impiego di un endoscopio per una gestione dettagliata contribuisce alla riduzione dei rifiuti delle risorse e promuove lo sviluppo sostenibile.

6. Conclusione

L'endoscopio industriale ad alta temperatura di 1000 ° C è senza dubbio un'importante innovazione nel campo della moderna ispezione industriale. Con la sua resistenza ad alta temperatura, design portatile, e capacità di sonda ultra-lunghe, Questo endoscopio trasforma i metodi tradizionali di ispezione delle attrezzature, Fornire vari settori efficiente, sicuro, e soluzione economica. L'uso di un endoscopio in ambienti ad alto rischio e ad alta temperatura migliora l'accuratezza delle ispezioni riducendo al minimo i rischi per il personale in loco, rendendolo uno strumento essenziale per la gestione della sicurezza e la manutenzione delle attrezzature di molte aziende. Mentre la tecnologia continua ad avanzare, Abbiamo tutte le ragioni per credere che questo endoscopio vedrà applicazioni più ampie in futuro, Contribuire alla sicurezza industriale e al processo intelligente.